Author: Site Editor Publish Time: 2025-08-30 Origin: Site

The biggest difference between tungsten and tungsten carbide is how they act and feel. Tungsten carbide punches work better than tungsten punches for tough jobs in factories. They are better because:

They are harder and last longer.

They do not get damaged by chemicals easily.

They work well when it gets very hot.

Tungsten punches are stronger but not as hard. Picking the right punch can help tools last longer and make better products.

Tungsten carbide punches are much harder than tungsten punches. They last longer too. This makes them good for hard jobs that wear tools out fast.

Tungsten punches can handle heat and do not rust easily. But they can break if hit hard or bent.

Factories use tungsten carbide punches for tools that must be exact and last a long time. These tools are used in cold forming, metal stamping, and other factory work.

Picking the right punch depends on what the job needs. You must think about the material, how hard it is, the heat, and how much you need to make. This helps save time and money.

Taking care of punches and getting expert help keeps them sharp. This makes them last longer and helps make better products.

Tungsten is a pure metal. It looks silver-gray and is very dense. It melts at about 3,422°C, which is very hot. This makes it one of the best metals for heat resistance. Tungsten rods and punches can handle high heat. They also block radiation well. Tungsten does not rust or react with most acids at room temperature. But tungsten is brittle. It can break if hit or bent. Because of this, it is hard to shape into detailed punches.

Property | Tungsten (W) |

|---|---|

Composition | Pure metal |

Melting Point (°C) | 3,422 |

Density | Very high (19.35 g/cm³) |

Hardness (Vickers HV) | 343–360 |

Structure | Crystalline metal |

Key Features | High melting point, corrosion resistance, brittle |

Tungsten punches are good when you need heat and chemical resistance. But they are not great for jobs with lots of hits or wear because they can break.

Tungsten carbide is not a pure metal. It is made by mixing tungsten and carbon. This makes hard grains that are stuck together with a binder, usually cobalt. Tungsten carbide punches are much harder than tungsten punches. Their hardness is between 1,700 and 2,400 HV. The structure has hard grains and a metal binder. This gives the punches both hardness and some toughness.

Aspect | Tungsten Carbide (WC) |

|---|---|

Composition | Tungsten + carbon (WC, W2C phases) |

Melting Point (°C) | 2,870 |

Density | Higher than steel, very dense |

Hardness (Vickers HV) | 1,700–2,400 |

Structure | Crystalline or amorphous, dual-phase |

Key Features | Extreme hardness, wear resistance, some brittleness |

Tungsten carbide punches are best for jobs that need high wear resistance and long life. They stay sharp and strong even when hot. These punches last longer than steel or tungsten punches. They are used for cold forming, metal stamping, and other tough jobs. Tungsten carbide punches work well in rough places and do not wear out fast.

Note: Tungsten carbide punches are harder and last longer than tungsten punches. But they can also be more brittle. You should pick the right punch for your job.

Tungsten is known for being very strong. It is a good choice for making tools. This metal melts at a very high temperature. It stays strong even when it gets very hot. Punches made from tungsten can work in hot places. They do not lose their shape or strength.

Mechanical Property | Value |

|---|---|

Tensile Strength | 550–680 MPa |

Young's Modulus | 411 GPa |

Vickers Hardness | 600–1200 Hv |

Elongation | 1% |

Fatigue Strength | 310 MPa |

Tungsten is hard and heavy. This makes it hard to cut or shape. But these features help punches keep their size and shape. Tungsten does not wear out or rust easily. It works well in tough places. When mixed with steel, tungsten makes steel harder. Tools with tungsten can cut fast and stay sharp longer. But tungsten can break if hit too hard or bent.

Tip: Tungsten punches are great against heat and rust. But they can break if used for jobs with lots of hits.

Tungsten carbide punches work very well in tough factories. These punches are made from tungsten and carbon. This mix is much harder than just tungsten. Tungsten carbide punches are usually about 90–92 HRA in hardness. This is much harder than most tool steels. Because of this, carbide punches do not wear out fast.

Tungsten carbide punches stay sharp and keep their shape after many uses.

They do not wear down quickly, so you do not need to change them often.

Tungsten carbide punches are very strong and do not get squished under heavy loads.

They also do not rust, so they are good for use in harsh or chemical places.

Tungsten carbide punches last longer than steel punches in big factories. They stay sharp and do not chip or get dull fast. This helps make better products and saves money. Many companies pick carbide punches for cold forming, die cutting, and metal stamping. Some companies add special coatings to make them even tougher.

Note: Picking the right kind of tungsten carbide punch is important. The best choice gives you the right mix of toughness and wear resistance. For special jobs, like edm tungsten carbide punches, you can get very exact shapes and smooth finishes.

Tungsten carbide punch tools are very important in factories. These punches work best when tools need to last a long time. They are used in car, airplane, electronics, and metal stamping factories. Tungsten carbide punch tools help make things like gaskets, seals, valve parts, and connectors.

The table below shows how factories use tungsten carbide punch tools. It also lists the parts they help make:

Manufacturing Process | Typical Applications / Industries | Examples of Components Produced or Operations Performed |

|---|---|---|

Cold Stamping / Punching | Automotive, Aerospace, Electronics, Metal Stamping Industries | Gaskets, seals, valve components, electronic lead frames, connectors, brackets |

Blanking | Sheet metal, plates, coils | Washers, gaskets, bushings, spacers, coin minting blanks |

Forming | Aerospace, automotive, electronics | Engine parts, airframe brackets, missile casings, wheel discs, hub caps |

Sheet Metal Punching | Construction, electronics, automotive | Punching holes in brackets, enclosures, motor/pump housings, electrical knockout holes |

Tungsten carbide punch tools come in many shapes. Some are flat, square, rectangle, hexagon, or offset. Factories pick the right shape for each job. These punches are made for making many parts at once. It usually takes 7 to 15 days to make mold accessories. If needed fast, samples can be ready in 1 to 3 days. How many parts are made depends on the number and shape of the parts.

Carbide punches are better than steel punches. They last longer and do not wear out fast. This means factories do not have to stop often to change tools. Carbide punches also keep their shape and sharp edge. This helps make good products and saves money.

Note: Factories sometimes need special carbide punches for unique shapes or sizes. These custom tools help make better products for special jobs.

Carbide punches are very important in cold forming. Cold forming shapes metal without using heat. This saves energy and keeps the metal strong. Tungsten carbide punch tools work well in cold heading and blind hole stamping. These jobs make things like bolts, screws, and rivets.

In cold heading, the punch die shapes the metal. Carbide punches can take high pressure and many hits. They keep their shape even after lots of use. For example, in airplanes, carbide punches can make over 800,000 hits in stainless steel. They keep edges straight within 0.003mm and surfaces smooth at Ra0.2μm.

Carbide punches also help with new ways of making things. Some have special coatings that make them last up to 300% longer. Smart systems can find early wear and stop problems. These features make carbide punches a good choice for making lots of parts.

Carbide punches give many benefits in cold forming:

They do not wear out fast and last longer than steel punches.

They keep tight sizes, which is important for making parts that fit.

They do not need to be changed often, which saves time and money.

They help keep product quality the same.

Tip: Checking and taking care of carbide punches helps stop problems and makes them last longer. Picking the right tool design and material is also important for best results.

Metal stamping uses dies and punches to cut or shape metal sheets. Tungsten carbide punch tools are used a lot in metal stamping and making precise parts. These punches can handle fast and strong hits without breaking.

Carbide punches are very hard and do not wear out quickly. They keep their sharp edge and size after many uses. This means they can make parts with exact sizes and smooth surfaces. Car, electronics, and building companies use carbide punches to make brackets, covers, and motor housings.

Making small holes and hard shapes often needs carbide punches. These punches help make many parts without changing tools often. This helps factories make more parts and waste less.

The main reasons to use tungsten carbide punch tools in metal stamping are:

They are very hard and can take strong hits.

They do not wear out fast, so they last longer.

They help make parts with exact sizes and good quality.

They save money over time, even if they cost more at first.

They are needed for fast stamping, where punches must stay sharp.

Note: Sometimes carbide punches can get burrs, break, or chip. Factories can stop these problems by using good tool design, checking tools often, and training workers. Special coatings can also help punches last longer.

Carbide punches are made by vacuum sintering. This makes them strong and hard. Carbide punches keep their shape and sharpness, even in fast and strong jobs. This means factories do not have to change tools often and can save money.

Custom carbide punches are made for special jobs. These tools help factories make better products. Carbide punches work well for both small and big jobs.

Block Quote:

"Tungsten carbide punch tools are very important in modern factories. They are strong, precise, and can be used for many jobs. This makes them the best choice for tough work.

Picking the right carbide punches means thinking about many things. Every factory job is different, so you must look at the material, the process, and what you want to make. Here is a checklist to help you choose:

Operating Conditions:

Check how hard the material is and how much space is between the punch and the hole. For example, stainless steel often needs a punch space of 12%–15% and a hardness of HRC 62–65.

Carbide Grade:

Pick the grade for your job. KG7 is good for very fine work and high accuracy. V30 is tough and works for thick metal. CD650 is best for making lots of parts over time.

Precision and Surface Treatment:

Find punches that are very exact, like edge straightness within 0.003 mm/m and diameter tolerance of ±0.001 mm. Special surface treatments, like mirror polishing or TiAlN coating, can help punches work better.

Structural Design:

Choose the right head shape and features that stop damage. A curve of at least 0.1 mm helps stop chipping.

Maintenance:

Follow rules for when to fix or sharpen punches. Check them often to keep them working well and lasting longer.

Customization:

You can get custom carbide punches for special shapes or needs. These help meet strict rules and make work faster.

Tip: High-precision carbide punches use the best materials and advanced methods. This keeps them very exact and working well, even in tough places.

Carbide punches are great because they do not wear out fast and keep their shape during fast stamping. They work well in hard jobs, but they can break if not handled carefully. Picking the right carbide grade gives a good mix of wear resistance and toughness. Cobalt and grain size are important for this balance. Using the right fluids, without sulfur or chlorine, helps stop damage and keeps punches working well.

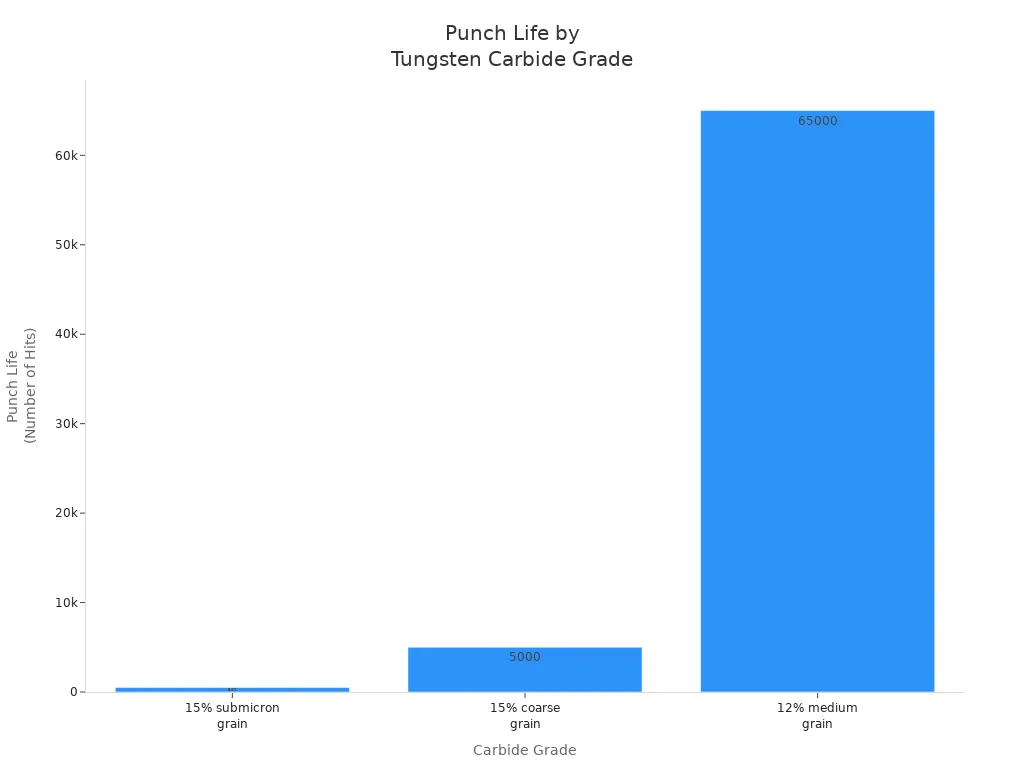

The chart below shows how different tungsten carbide grades change punch life. Smaller grains make punches harder and more resistant to wear, but also more likely to break. Bigger grains make punches tougher but less resistant to wear. The best mix makes punches last longer and saves money.

Choosing between tungsten and tungsten carbide punches depends on what you need. Each one has good and bad points. The table below shows the main properties and costs for each punch type:

Punch Type | Initial Unit Price (USD) | Minimum Order Quantity | Key Attributes and Cost Considerations |

|---|---|---|---|

Tungsten Carbide Punches | $5 - $10 per piece | 100 | High precision, superior wear resistance, longer lifespan, higher upfront cost but lower replacement frequency and downtime |

Tungsten Steel Punches | $0.50 - $0.80 per piece | 2 | Customizable, moderate durability, lower upfront cost, balance between cost and performance |

Steel Punches (CR-V) | $0.63 - $0.70 per piece | 1000 | Lowest upfront cost, widely available, requires high volume for best pricing, shorter lifespan, potentially higher indirect costs due to wear and failure |

Tungsten carbide punches cost more at first, but they last much longer in hard jobs. This means you do not need to replace them as often, so you save money and time. Tungsten steel and regular steel punches are cheaper at first, but they wear out faster and need to be changed more. For big jobs or jobs that need high accuracy, carbide punches are usually the best choice.

When picking between tungsten and tungsten carbide, think about these things:

Hardness vs. Toughness:

Tungsten carbide is harder and resists wear better. It is best for rough, big, or very accurate jobs. Tungsten steel is tougher and costs less for normal jobs.

Application Temperature:

Tungsten alloys can take higher heat. They are good for airplane and car factories.

Machinability:

Tungsten carbide is harder to shape. It needs special tools and skilled workers.

Production Volume and Precision:

Big jobs and jobs that need exact sizes are better with carbide punches because they last and keep their shape.

Material Thickness and Type:

The kind and thickness of metal matter. Aluminum may need sharper angles, while carbon or stainless steel need wider angles.

Compatibility with Machinery:

Make sure the punches fit the machines for smooth work.

Environmental Conditions:

Some places cause more wear or marks. Pick materials that can handle these problems.

Supplier Support:

Getting help from experts makes it easier to pick and use the right punches.

Note: Carbide punches are twice as hard as steel punches. This makes them last longer and resist wear better. In tough jobs, they last longer and help save money by reducing downtime.

How many parts do you need and how exact must they be? 2. What kind and thickness of material will you punch? 3. Does the job need high wear resistance or toughness? 4. What temperature will the punch face? 5. Is saving money over time more important than the first price? 6. Does the punch need to fit certain machines? 7. Do you need custom carbide punches for special shapes or sizes? 8. Can you get help from the supplier for questions?

Block Quote:

"Picking the right punch material helps tools last longer, makes better products, and helps the whole factory work better."

Carbide punches are best for jobs that need high accuracy, lots of parts, or are very hard. They last a long time and are a smart buy, especially when you want to save money and stop work delays.

Aspect | Tungsten Punches | Tungsten Carbide Punches |

|---|---|---|

Hardness | High, but brittle | Extremely hard, less brittle |

Wear Resistance | Moderate | Superior |

Typical Use | Electrical, thermal | Stamping, forming, tooling |

When picking a punch material, you need to think about hardness, wear resistance, and toughness. It is important to check what material you will work with. You should also look at the punch design and any coatings. Talking to tooling experts can help a lot. They give advice so you do not make mistakes. Experts help you choose punches that fit your job best.

A punch pin helps shape, cut, or form metal or plastic. Factories use punch pins in stamping and molding jobs. They also use them for die-cutting. Punch pins help make parts with the right size. They also help make smooth edges on parts.

Factories like tungsten carbide punches because they last longer than steel punches. These punches do not wear out fast. They keep their sharp edge and shape after many uses. This helps factories save money and stop work delays.

Tungsten carbide rods make punch pins harder and stronger. These rods help punch pins not bend or break. They also help punch pins not wear out fast. Punch pins with tungsten carbide rods work well in tough jobs. They are good for making lots of parts.

Yes, companies can make punch pins in special shapes or sizes. Custom punch pins help factories meet strict rules for parts. They also help make parts faster. Special coatings or designs can help punch pins last longer.

Factories should check tungsten carbide punches often for damage or wear. Cleaning and storing them right stops rust and chipping. Taking care of punches keeps them sharp and helps them last longer.