Product Advantage

Product quality

The degree of standardization of molds has beenfurther improved to meet customers' newdevelopment needs through standardized technical

design.

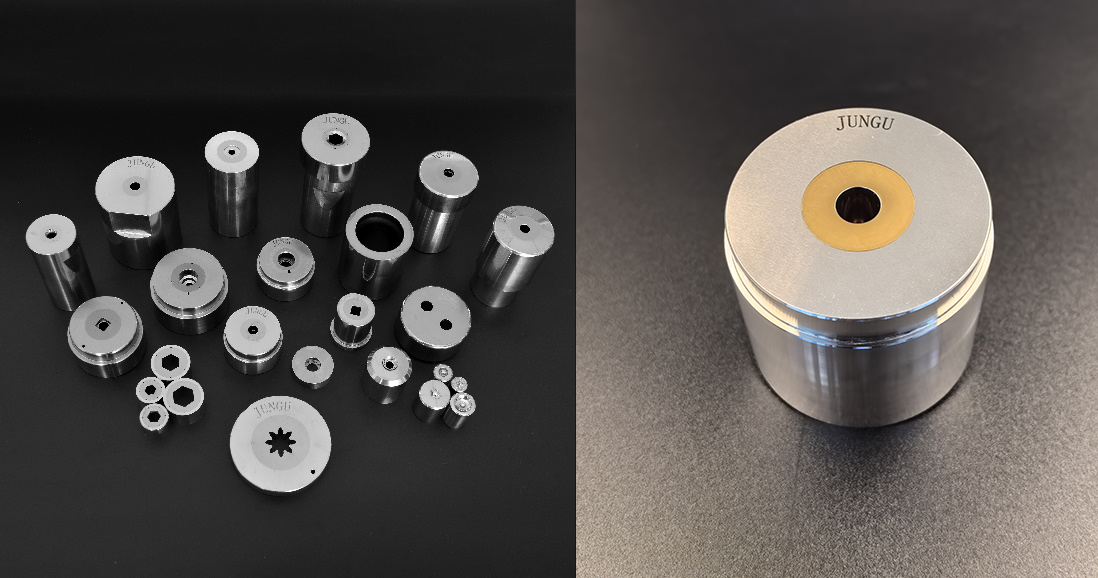

Advantage of the number of molds

After years of development, the number of moldmodels produced has exceeded 50.000, which carmeet the needs of most customers. This strongadvantage of the number of molds enables theproducer to provide diversified products and adapt tothe needs of different models.

Advantage of the number of molds

Supporting customized fastening solutions, it can beadapted to a wide range of vehicle models andprovide user-friendly services.

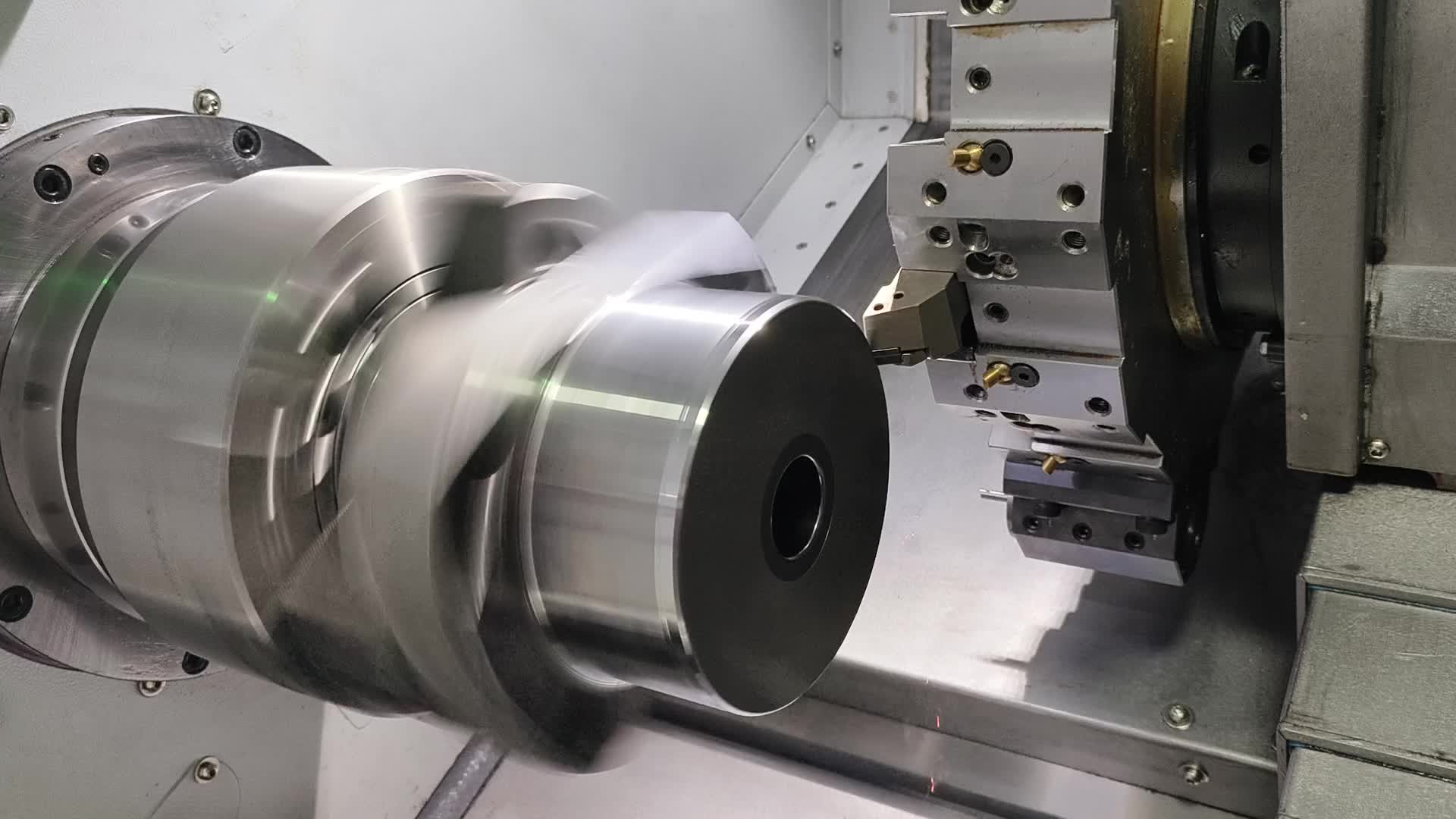

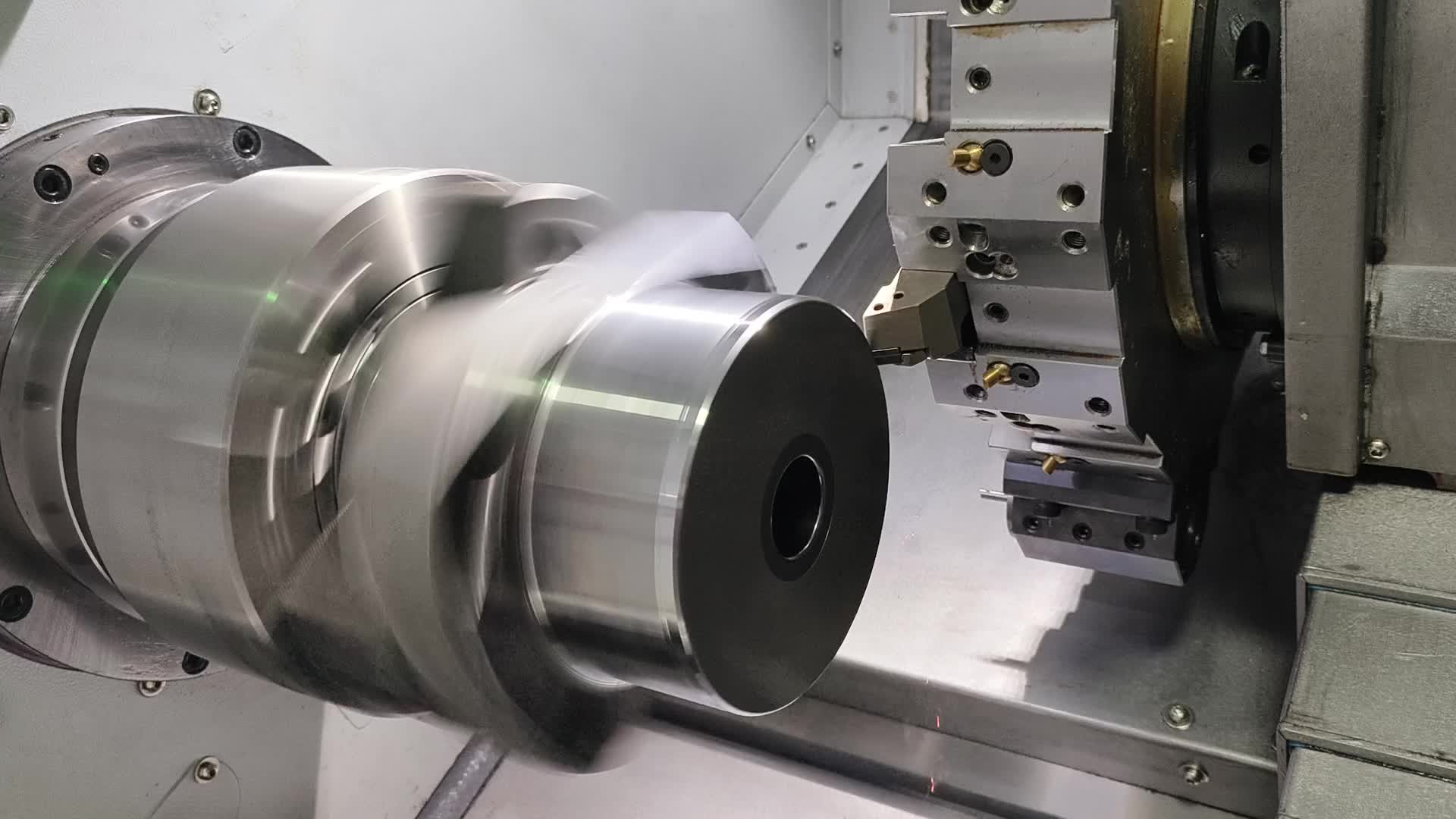

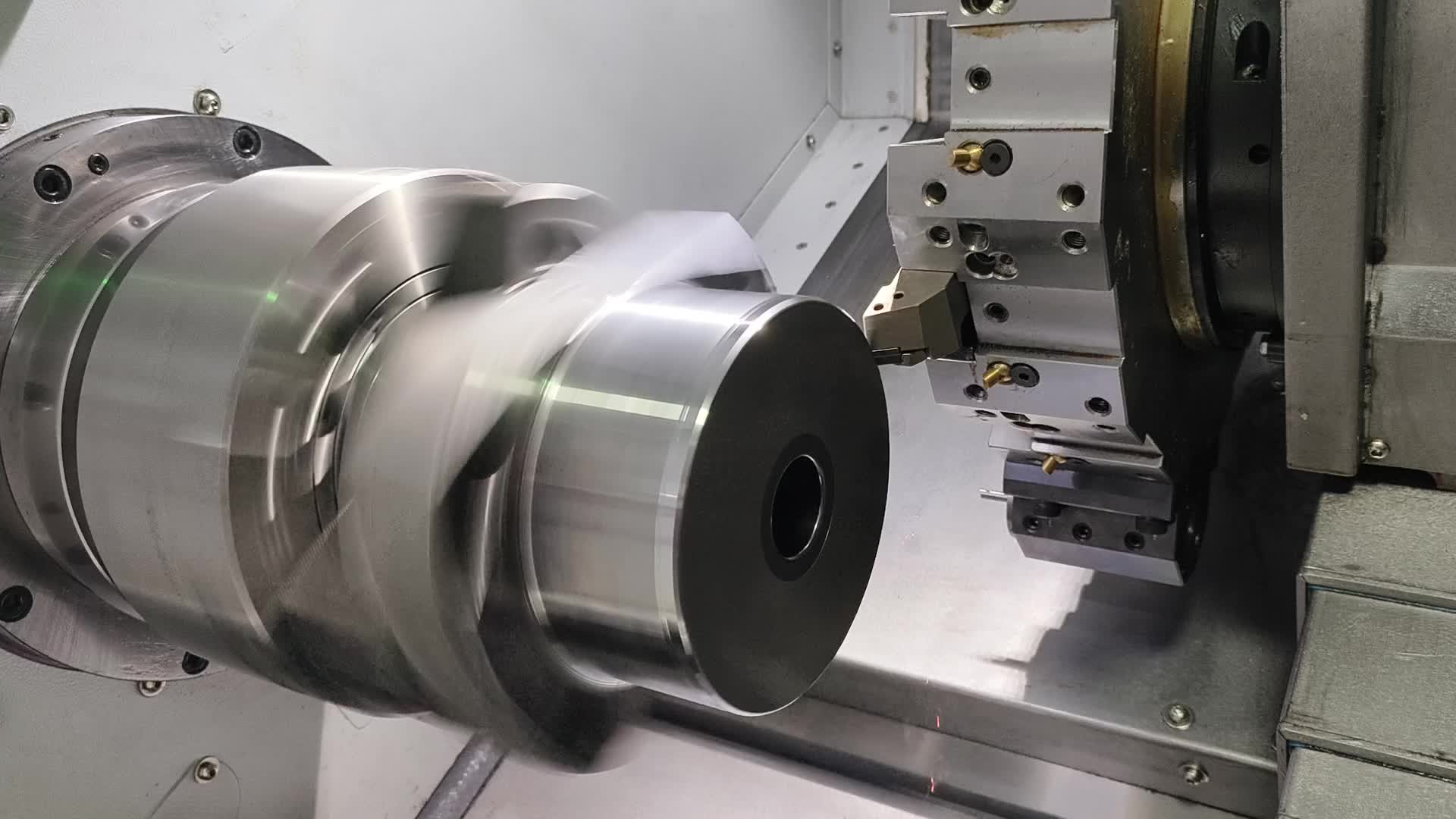

Mold precision and manufacturing process

Advanced production and testing equipment,focusing on the precision of molds and manufacturing process.High-precision molds and exquisite manufacluring processcan not only extend the service life of fasteners, but also provide customers with more accurate products.

Technological advantages of three-pronged approach to design, software and equipment

The vaious aspects ofthe design and producion of the covering part mold reguire high level of equipment and technology, and ithas obvious technical advantages. interms ofresearch and development equipment,we have adopted a variely of advanced measurement means and intemmational advanced level oflarge-scalemeasurement eauipment and technology to ensure the precision and efficiency of the products.

Why Choose Us

Not only is it in the leading position in design technology, but it also integrates many years of practical experience and establishes an international advanced level, including the application of computer software, which realizes 100% CAE analysis of the production parts, 100% full mold CAE analysis of production parts, 100% 3D solid design of molds, 100% anti-interference check of mold design, 100% CNC machining of real molds, etc., which ensures the high quality and efficient production of the products.

Product Type

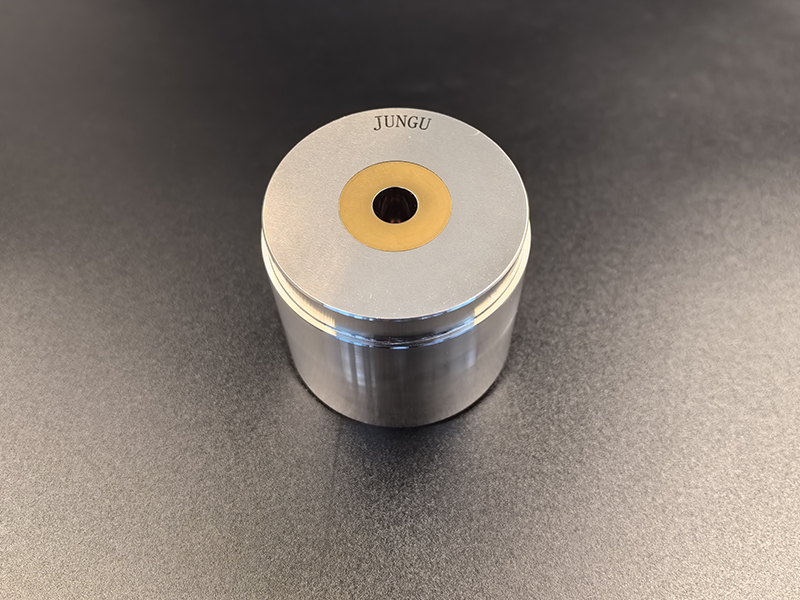

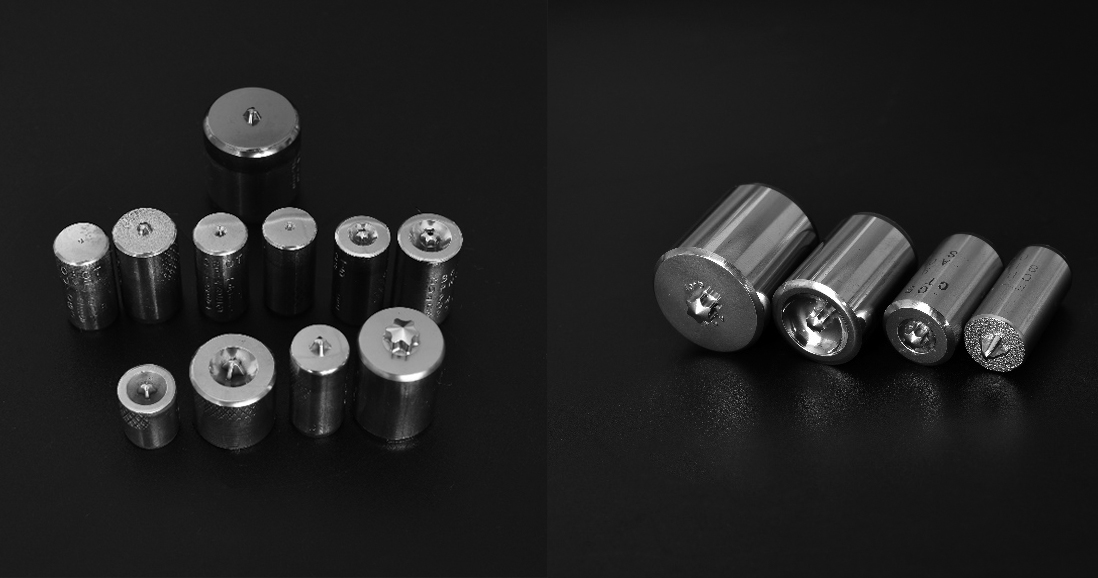

High Precision Carbide Bolt Die Used For Cold Forging

The tungsten carbide bolt die consists primarily of a tungsten carbide insert and a die steel case. Tungsten carbide offers exceptional properties such as high strength, superior abrasion resistance, outstanding hardness, and excellent temperature resistance. These characteristics significantly enhance the service life of the mold while ensuring compatibility with the production of nuts made from various materials.

Our nut dies stand out for their premium quality, high precision, and prompt delivery.

High Precision Carbide Die Nut Used For Cold Forging

The tungsten carbide nut die consists primarily of a tungsten carbide insert and a die steel case. Tungsten carbide offers exceptional properties such as high strength, superior abrasion resistance, outstanding hardness, and excellent temperature resistance. These characteristics significantly enhance the service life of the mold while ensuring compatibility with the production of nuts made from various materials.

Our nut dies stand out for their premium quality, high precision, and prompt delivery.

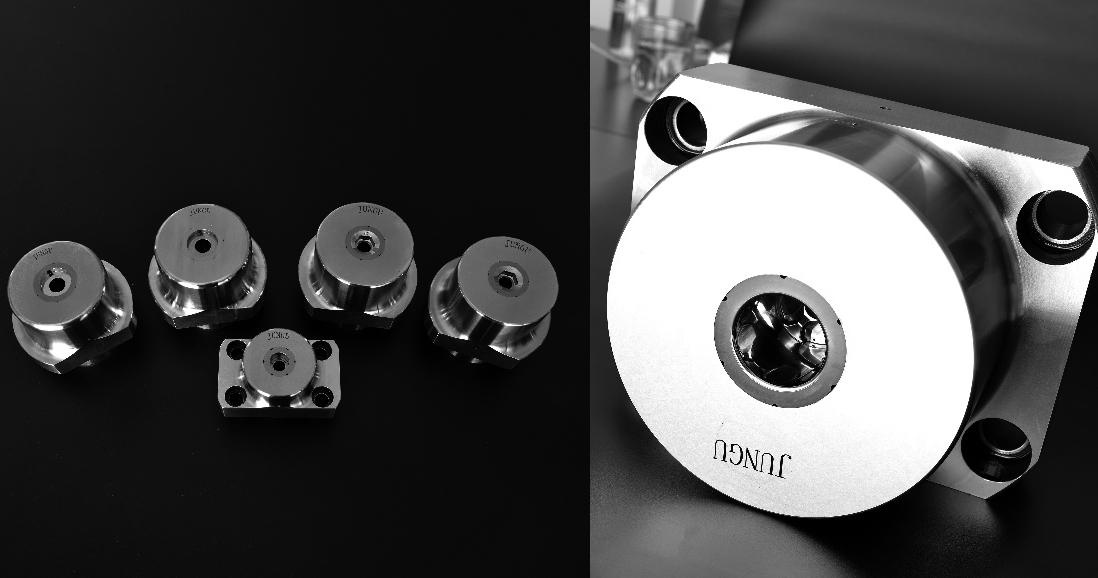

Manufacturer High Precision Punch Set Metal Punch

We provide high-performance carbide punches for aerospace and automotive component manufacturers, using high-quality tungsten carbide materials, custom-optimized designs, and excellent hardness and wear resistance, which help clients achieve breakthrough machining results by improving machining accuracy, surface quality, and productivity, as well as reducing the frequency of replacement.

High Quality Metal Punches Pin Punch Set

A head punch is a metal part mounted on a stamping die, also known as a convex die, upper die, male die, punch, etc.

High-Precision Thread Rolling Dies for Screws And Bolts

Thread rolling dies operate primarily through cold extrusion molding, shaping threads using the screw light nail extrusion technique. The teeth of these dies are typically cold-rolled with needle rollers, enabling them to withstand significant impact loads and extrusion stresses post heat treatment. This processing method not only enhances the efficiency and reduces costs of production but also ensures the quality of the threaded components.

In industrial settings, thread rolling dies find extensive use in screw and bolt manufacturing facilities for the mass threading of small bolts. Advancements in technology continuously drive enhancements in thread rolling dies to cater to increasingly specialized application requirements.

Tools And Accessorie Parts

Enhance your tooling capabilities with our comprehensive range of Tools and Accessorie Parts, designed to meet the demands of precision engineering and industrial applications. Our collection includes high-quality punch dies for press, durable punch and dies systems, and versatile punch kits that cater to all your pressing and punching needs. Whether you're looking for reliable punch pins, sturdy punch pin holders, or complete punch sets, we have the solutions to optimize your workflow. Explore our selection of punch roll pins and punch press dies, engineered for exceptional performance and longevity. Trust our punch pins and punch pin holders to deliver unmatched stability and accuracy, ensuring your operations run smoothly and efficiently. Upgrade your toolkit with our premium Tools and Accessorie Parts today!

(Japan Sankyo Sputtering and Polishing Machine) Equipment Agent

Specially designed for industrial surface treatment, using high-pressure sandblasting technology to efficiently remove oxide layers, optimize roughness, and deburr polishing. Core advantages: Intelligent frequency conversion control saves 30% energy, digital pressure regulation accurately adapts to process requirements, fully enclosed design equipped with efficient dust removal, safe and environmentally friendly. Widely used in automotive components, aerospace parts, electronic components, and mold repair, compatible with multiple materials. Provide 24-hour technical support and customized solutions to assist in efficient production.

Application

Automotive industry

Aerospace industry

Industrial machinery industry

New Energy industry

Medical machinery industry

Electrical industry

Get Touch With Us

CONTACT INFO

+86-13764335488

+8613764335488

Building 3, Chuangrui Technology Industrial Park, No.198 Renmin North Road, Taicang City, Suzhou, Jiangsu Province, China.