Author: Site Editor Publish Time: 2025-08-25 Origin: Site

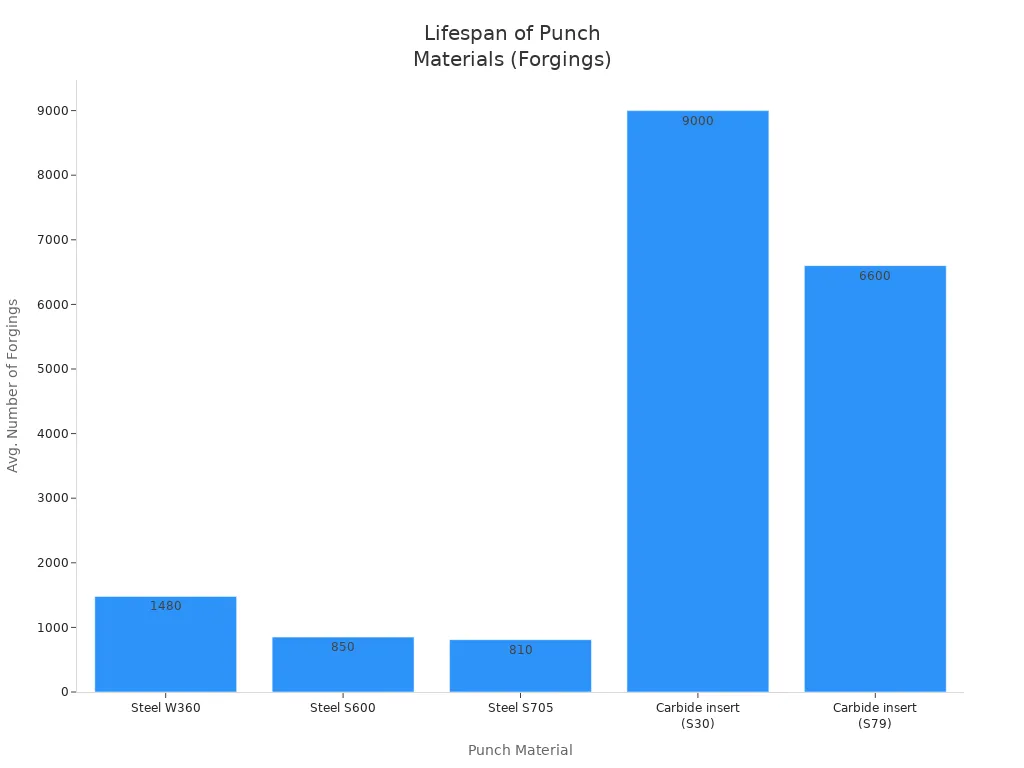

Tungsten carbide punches are very hard and tough. They do not wear out easily. These punches help shape, pierce, and form metals and plastics. They work with dies in cold forming and stamping. Carbide punches last much longer than steel punches. The table below shows how long each punch lasts. Carbide inserts can last up to 9000 forgings. Steel punches often break before 1500 forgings.

Punch Material | Hardness (HRC) | Average Number of Forgings (pieces) |

|---|---|---|

Steel W360 | 58 | 1480 |

Steel S600 | 61 | 850 |

Steel S705 | 60 | 810 |

Punch with carbide insert (S30) | 1340 HV | 9000 |

Punch with carbide insert (S79) | 1600 HV | 6600 |

The Carbide Punch Rod Industry Research Report 2025 says more people use tungsten carbide punches and carbide punches in dies all over the world. The biggest markets are in the United States, China, and Germany. Manufacturers use these tools to work faster, stop machines less, and save money.

Tungsten carbide punches last longer than steel punches. This helps factories save time and money. They do not need to change tools as often. There is also less downtime.

Using high-grade carbide material makes punches stronger. Following strict rules when making them helps them work better and last longer.

Good punch shapes and the right clearance lower wear. This helps punches cut better and last longer.

Setting machine parameters correctly is important. Using the right lubrication helps too. Matching punches to the right materials stops early tool failure.

Cleaning punches often keeps them in good shape. Storing them carefully helps too. Doing maintenance on time makes carbide punches last longer.

Tungsten carbide punches are special tools in factories. They are very hard, about 9 on the Mohs scale. This hardness helps them not wear down or bend easily. They keep their sharp edges even after many uses. These punches are strong and tough, so they do not break when hit or bent.

Carbide punches last a long time because they resist wear. They work well in places with lots of friction, like metal stamping. They stay hard even when it gets very hot, up to 1000°C. They do not change shape much when heated quickly. These punches also do not rust, so they work well in tough places.

Some important mechanical properties are:

Extreme hardness helps them stay sharp longer

High strength and toughness stop them from breaking

Great wear resistance means they last longer

Thermal stability and low expansion help in fast jobs

Corrosion resistance keeps them working in rough areas

These features make tungsten carbide punches good for precise work. They keep their shape and size under pressure and friction. This helps make parts that are the right size and quality every time.

Tungsten carbide punches are used in many factory jobs. They work with dies to shape, cut, and form metals and plastics. Their main jobs are cold forming, stamping, piercing, and shaping. These punches help make parts for industries that need accuracy and strength.

Factories use tungsten carbide punches for:

Cold forming: shaping metal without heat to save energy

Stamping: pressing dies into metal sheets to make parts fast

Piercing: making holes with sharp, clean edges in sheets

Shaping: forming complex shapes in metals and plastics

Cutting: trimming or slicing materials during production

These punches are better than steel punches in many ways. They last longer, so factories do not need to replace them often. Their strength helps keep machines running and saves time. Carbide punches keep their size, so every part is made right. This means less waste and fewer mistakes.

Tungsten carbide punches are important in industries that need lots of parts made quickly and accurately. Car makers, airplane builders, and electronics companies use them for mass production. Medical device makers and tool companies also use them for making precise parts.

Tungsten carbide punches are mostly used in jobs with dies and punches. These jobs include stamping, molding, and shaping metals and plastics. Their hardness and wear resistance help them last a long time. They work well under high pressure, which saves money and makes parts more accurate.

The table below lists some industries that use tungsten carbide punches:

Industrial Sectors Using Tungsten Carbide Punches |

|---|

Automotive |

Aerospace |

Defense / Military |

Medical |

Electronics |

Telecommunications |

Consumer Products |

Semiconductor |

Energy |

Utilities |

Agriculture |

Mining |

Petroleum |

Pulp and Paper |

Fluid or Food Processing |

Machine Tooling |

Tungsten carbide punches help factories work faster. Their hardness and wear resistance let them handle lots of use. This means tools last longer and need fewer changes. Less downtime helps keep production lines moving.

Carbide punches also keep their size very well. This makes sure every part meets strict rules for quality. Factories save money by making less scrap and doing less rework. Even though these punches cost more at first, they save money over time. They also make parts with smooth surfaces, so extra finishing is not needed.

High-grade carbide helps punches last longer and work better. Factories using these punches do not need to change tools as often. This means machines stop less, so work goes faster. High-grade carbide costs more at first, but it saves money later. These punches break less and last longer. They also make smoother surfaces and help machines run well. Lower-grade carbide is okay for easy jobs, but it does not last in hard jobs. It breaks sooner, so factories must change tools more. This makes costs go up.

The table below shows how different carbide grades work in punch tools:

Carbide Grade Type | Grain Size & Cobalt Content | Performance in Punch Tool Application | Tool Life (Hits) | Failure Mode |

|---|---|---|---|---|

Grade 1: Submicron 15% Co | Submicron grain, 15% cobalt | Early chipping due to poor surface quality and corrosion | ~500 hits | Pullback chipping and galling leading to punch destruction |

Grade 2: Coarse Grain 15% Co | Coarse grain, 15% cobalt | Excessive wear after moderate use | ~5,000 hits | Wear degradation |

Grade 3: Corrosion-resistant Medium Grain 12% Co | Medium grain, 12% cobalt, corrosion resistant, high surface quality, virgin material | Superior wear resistance and toughness, significantly longer tool life | 50,000 hits (up to 80,000 with lubrication) | Minimal chipping, high durability |

High-grade carbide with the right mix can last up to 80,000 hits. This is true if you use the right oil or grease. Fewer tool changes mean more time making parts. Factories using high-grade carbide punches save money and get better results.

Strict rules in making punches help them work in all dies. Top companies use new ways to make these tools. They use special heat and coatings to make punches harder. Some factories use 3D printing and machines that move in many ways. These new ways help make punches that fit well and last longer.

Better carbide processing makes punches stronger and work better.

Factories can order punches made for special dies.

Robots and machines help make punches very exact.

New coatings and materials protect punches from heat and wear.

Punches made with high standards keep their shape after many hits. This helps factories make parts that meet tough rules. Good making also means less waste and fewer mistakes. Factories that pick the best punches see fewer tool problems and better work in their dies.

The shape of a punch tool plays a big role in how long it lasts and how well it works with dies. Engineers design punches with special profiles to match the needs of each job. They look at the thickness of the material and the type of cutting needed. A punch with the right shape reduces the force needed during cutting and helps the punch last longer. For example, a convex double-shear angle of about 20° gives better results than smaller angles. This shape helps the punch make cleaner holes and keeps the edges sharp after many uses.

Punch-die clearance is also important. The space between the punch and the dies must be just right. If the clearance is too small, the punch wears out faster and may break. If it is too large, the edge quality drops. Most factories use a clearance between 5% and 20% of the material thickness. This balance helps reduce stress on the punch and improves the quality of the cutting. Finite Element Analysis shows that changing the clearance for different shapes can make wear more even and help the punch last longer.

Manufacturers use tests and computer models to find the best blade angles and shapes for each job. They often choose blade angles between 27.5° and 29° for different types of punches. This careful design helps the punch work well with many types of dies and materials.

Special design features help reduce wear on carbide punches. Nano-grooved edges, for example, control how the material flows during cutting. Grooves at 20° and 90° angles can lower the damage from work hardening. The Nano90° groove reduces the work hardening zone by up to 69% compared to normal punches. This means the punch stays sharp and strong for more cycles.

Other features, like flatter tablet profiles and compound radii, help keep the punch from wearing out too fast. These shapes stop small particles from getting trapped between the punch and the dies. Coatings such as TiC make the punch surface harder than steel. These coatings can make the punch last up to 900% longer. They also help prevent sticking and rust.

Common mistakes in punch design can lead to early failure. Misalignment between the punch and the dies causes uneven pressure and more wear. Using the wrong clearance or too much stroke depth can also damage the punch. Factories avoid these problems by checking alignment and making sure all parts fit tightly. Good design and setup help punches work better and last longer in all types of dies and cutting jobs.

Operators need to set the right settings for carbide punches. This helps them last longer in dies. Using tungsten-cobalt carbide makes punches and dies stronger. They can last 20–30 times longer. Factories should use good forging and heat treatment. This stops the punches from breaking or bending. High machining accuracy is very important. Holes must be spaced just right. Punches should be straight up and down. The space between the die and punch must be even. Smooth surfaces help lower friction and wear.

A strong press machine is needed. It must have enough power and not bend. The machine’s power should be at least 30% more than the punching force. This keeps the dies safe from shaking and damage. The space for cutting and forming must be checked. Making the space a little bigger can help dies last longer. This does not hurt the part quality. Using the right oil or grease lowers friction and heat. This stops the tool from failing early. Regular care, like sharpening and checking, keeps punches and dies working well. Operators should stop using dies if they see damage or problems.

Tip: Keep the ram level and lower vibration. This helps dies and punches last longer.

Setting up the die the right way is important. The die must be in the right spot. Offloading and shut height must be correct. This keeps forming smooth. The right oil or grease must be used and put on the right way. Factories should not use too much force. They should check the space between parts. If the space is too small, friction goes up and tools wear out faster. Good care, like grinding and cleaning, helps tools last longer. Changing old die parts, like coil springs, also helps tools last longer.

The punch and workpiece must match well. This affects how fast tools wear out in dies. Soft metals like aluminum can stick to the punch. This makes layers build up and wears out the tool faster. It can also make the tool fail early. The workpiece’s properties, like how it handles heat and how easy it is to cut, change how punches wear out.

Soft metals, like aluminum, can rub off onto the carbide punch. This makes the punch rougher and causes more wear. This is called galling. More friction and roughness make the punch wear out faster. The makeup of the carbide punch can change how much metal sticks and how much friction happens. Binderless carbide grades have less friction and less metal sticking. Tiny bumps on the punch can start aluminum sticking. Softer metals cause more wear and make punches not last as long.

Factories should pick punches and dies that fit the workpiece. Good matching lowers tool wear and keeps the punch in shape. It also stops early tool failure. Following ISO 3685 helps factories check and control tool wear in forming jobs.

Cleaning and storing carbide punches the right way helps them last longer in dies. Operators should not drop or hit punches. Carbide is very hard but can crack if hit. Punches should be kept in holders or cases. This keeps them safe from damage and rust. Factories put coatings on punches before storing them. These coatings lower friction and help stop rust. They also help punches work better in dies.

Workers clean and check punches between jobs. This helps them find damage early. It stops punches from breaking during use in dies. Factories that work with good tooling providers get punches made to fit well. These punches last longer in dies. Checking routines look for chips, cracks, and dull edges. Workers also check for loose parts in dies. Keeping records of punch use helps plan when to do maintenance.

Tip: Clean punches after each use. Store them in a dry, neat place. This stops rust and keeps punches safe.

Lubrication helps carbide punches last longer in dies. Factories use solid film, soap, wax, and special coatings like MoS2. These lower wear when punches work under high pressure and heat in dies. Metal and plastic films also help, but they need the right thickness. If they are too thin or rough, they break down in dies.

Coatings like TiN and AlCrN make punches stronger. They are put on by PVD. These coatings help punches last longer in dies. Some coatings have MoS2 and Al2O3. They make a film that lowers friction and cutting force in dies. If punches run without lubrication, they wear out much faster. Lubrication stops galling and overheating. These are big reasons punches wear out in dies.

Doing regular care, like adding lubrication and checking punches, helps factories save money. It lowers downtime and replacement costs in dies. Factories that do these steps have fewer problems and keep working smoothly.

Manufacturers can make carbide punch tools last longer by focusing on five main things: material quality, tool design, correct use, maintenance, and lubrication. These steps help punches work longer in dies and lower downtime. They also help save money. The table below shows some real benefits:

Benefit Description | Quantifiable Impact |

|---|---|

Reduction in tool replacement costs | Up to 40% savings |

Faster tool sharpening | Less than 5 minutes per tool |

Increased production throughput | More parts made in less time |

Industries that use these steps in dies have smoother work and better quality. Car and electronics companies say they waste less and get better results. Using these good habits keeps dies working well and helps save money for a long time.

A Punch Pin is a special tool that shapes or makes holes in materials. It is made with tungsten carbide to be extra hard. Regular punches are often made from steel. Punch Pins with tungsten carbide last longer and work better when making lots of parts.

Factories can make punches last longer by using high-quality tungsten carbide rods. They should keep punches clean and use the right oil or grease. Checking for damage often helps too. Setting machines the right way also helps punches last longer and keeps work moving.

Tungsten carbide punches are much harder than steel punches. They do not wear out fast and keep their shape after many uses. This means factories change them less, stop less, and make better parts.

Workers should clean Punch Pins after using them. They need to store them in dry holders and look for cracks or dull spots. Using the right oil and not dropping them helps Punch Pins and tungsten carbide punches stay strong.

Yes, factories can use tungsten carbide rods to make custom Punch Pins. These rods can be shaped into special sizes and forms. This helps make tools for different jobs in many industries.